We provide the building blocks needed to achieve the measurements your application requires.

Let us help you build a successful measurement chain for your application.

imc STUDIO 2025 is now available, delivering powerful upgrades to the industry-proven test and control software platform. This release introduces WFT assistant with driver remote control, enabling safe, high-speed wheel balancing directly from inside the vehicle—ideal for track testing and prototype validation.

Key upgrades also include enhanced Python integration for real-time data workflows, digitally signed software files for improved cybersecurity, and simplified sensor scaling with new unscaled range parameters. These updates support faster configuration, more efficient scripting, and greater system transparency.

Explore the latest version with A-Tech

A-Tech Instruments is proud to announce a new strategic partnership with PINpoint Information Systems, a global leader in Manufacturing Execution System (MES) software. This collaboration brings PINpoint Essentials, a powerful, no-code MES platform, to a broader range of discrete manufacturers across Canada.

Designed for fast deployment and seamless integration, PINpoint Essentials delivers:

- Real-time production visibility and full traceability

- Integrated automation with smart tools, sensors, and robotics

- Digital work instructions, error-proofing, and operator guidance

- Insightful dashboards and KPIs to expose inefficiencies and optimize throughput

With this partnership, A-Tech expands its commitment to delivering end-to-end smart manufacturing solutions—from precision instrumentation to complete digital control systems.

imc Test & Measurement announces the release of imc STUDIO 2024, the latest version of their comprehensive test and measurement software.

This update enhances functionality with efficient metadata management for detailed documentation of measurements, a Python® interface for advanced data analysis, and convenient calibration support for measurement microphones. Additionally, it features improved reaction speeds when working with large configurations of hundreds of active channels. The software also ensures compatibility with both current and previous generations of imc systems, including the new imc ARGUSfit data logger, providing a seamless integration for all users.

Noraxon is set to release MR4, the latest version of its innovative software, designed to enhance workflow efficiency with advanced features tailored for data-driven environments. This new software update includes an improved user interface that simplifies navigation and tool access, making it more user-friendly.

Key features of MR4 include:

- Enhanced Layout: Streamlined navigation and contextual tool access.

- 2D Markerless Video Analysis: Advanced tools for analyzing dynamic activities such as walking, running, and other movements.

- Updated Ergonomics Toolkit: Tools for better safety and efficiency in workplace ergonomics assessments.

- Multi-User Access Database: Enables seamless collaboration across multiple workstations with enhanced data security.

MR4 is compatible with existing systems, ready to integrate and elevate your data analysis capabilities. Keep an eye out for its release – a smarter, more efficient solution for your professional needs.

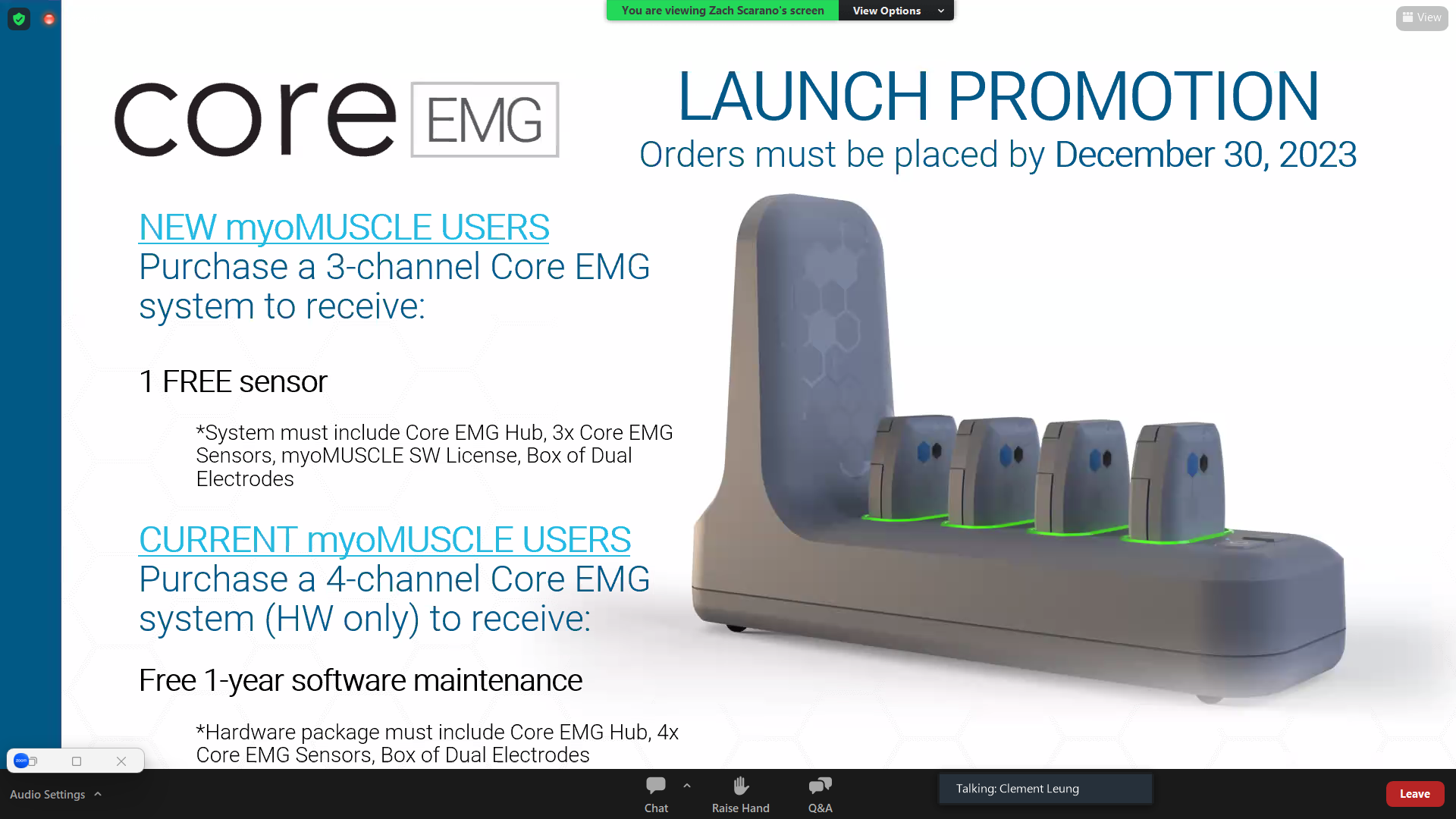

Noraxon has just released the new Core EMG system that provides quality EMG measurements in an affordable package for clinical application. The wireless EMG systems are offered with 2 or 4 sensors, and are complete with the receiving / charging hub and software application.

- 2 or 4 sensor systems that include data collection software

- can be used with the latest version of myoRESEARCH 3 software

- Supplemental system to Ultium EMG systems

- Li-Ion Coin cell battery can be replaced by factory representatives in Canada

- Can sync multiple hubs, for an 8-channel system